Simple Diy Pcb With A 3D Printer. Import the files to the 3d printer, and then the 3d printer will complete the work. Pcb board, a bottle of ferric chloride, a mini drill, a small container, a bottle of thinner and some plastic tweezers.

Some desktop 3d printers only have a small build volume, so cowtech designed parts that can be printed on any printer with a build volume of 115 x 110 x 65 mm, which almost all 3d printers have. When it is done you'll have a 1.6mm thick, double sided pcb with all the artifacts you'd expect on a professionally fabricated pcb including tracks, pads, vias and variable sized holes. I would start with the top side, and drill two holes at two (or four) corners of the pcb (0,0 and 80,80) just before etching the topside.

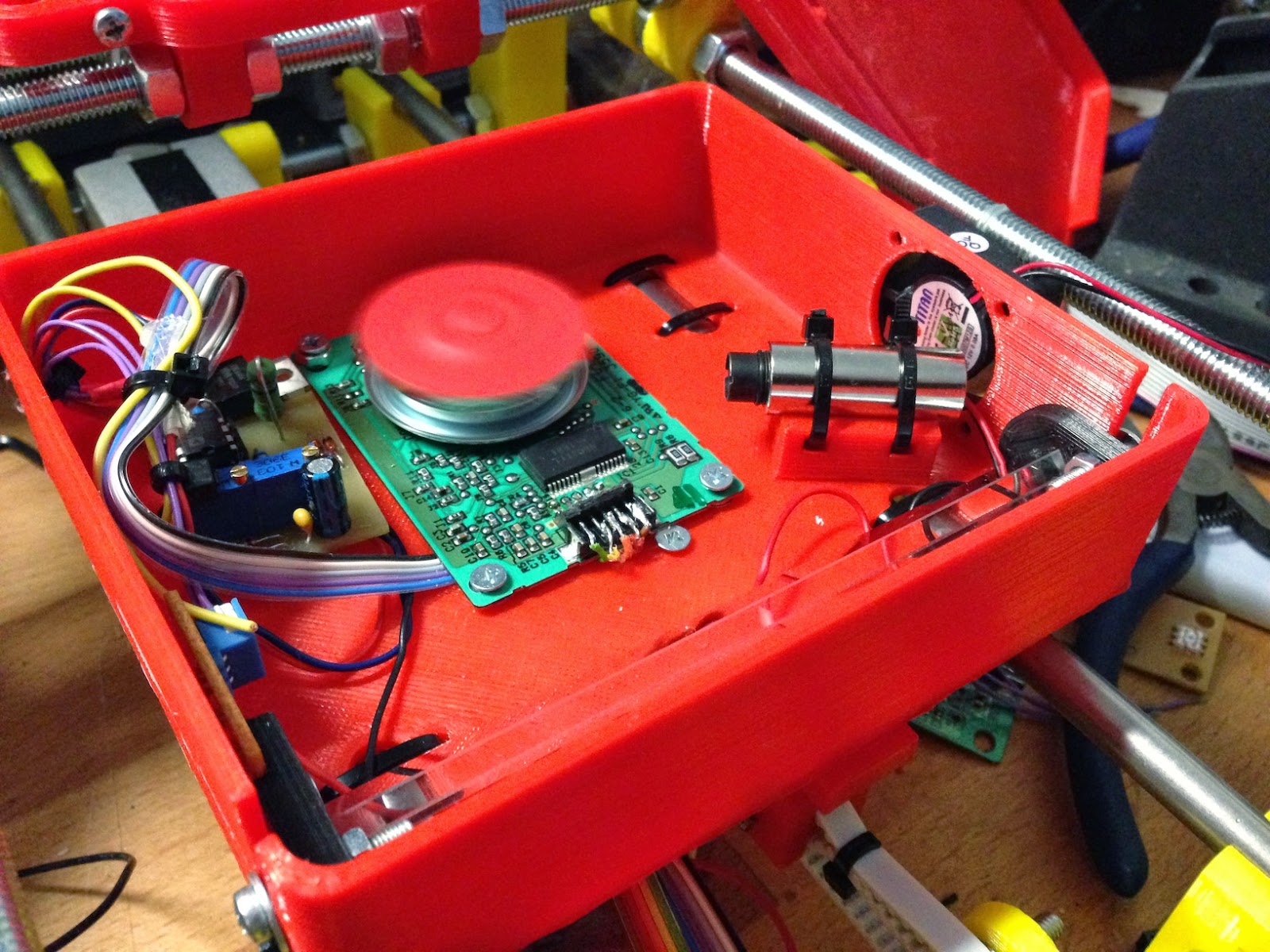

Delve Into Making Your Own 3D Printed Circuit Boards.

Be ready to spend about 6 hours of intense maker fun on building one of these units. Transfer the pcb print onto the copper plate. An interactive robot that anyone can make!

With A Large Build Volume Of 220 X 220 X 250 It Can Achieve Quiet Large Print Projects.

We need to create this trace and meander it onto a pcb. Even if you have the required equipment and conductive filament for making a pcb with a 3d printer, you are only halfway to your goal of 3d printing your own pcbs. Or even build a simple control device with an sdcard and a microcontroller,.

We Have A Trace Length Of 2 Meters And A Trace Width Of 10 Mil (0.254Mm).

With all the cool and useful parts you can whip up (relatively) quickly on a 3d printer, it’s a. Arduino 3d printers are a rare breed indeed. If playback doesn't begin shortly, try.

If Playback Doesn't Begin Shortly, Try Restarting Your Device.

The minimum layer thickness is 30 μm or 0.03 mm. Instead, all the heads are magnetically mounted and attach with a satisfying snap. It is posible to create a double sided pcb, but this requires 2 gcode files:

Following Are The Steps On ‘How To Etch A Pcb.’ 1) Design & Printout Your Pcb Schematics.

It’s cheap if you cut out the size you need and tape it to a regular sheet of paper before sending it through the printer (only tape the edge that goes in to the printer first). It is as this point that we have to decide a trace separation and heater dimension. Before you can create your own printed circuit board (pcb), you need to design your board on a computer.

0 Comments